Textile Machinery Audit Mobile Application

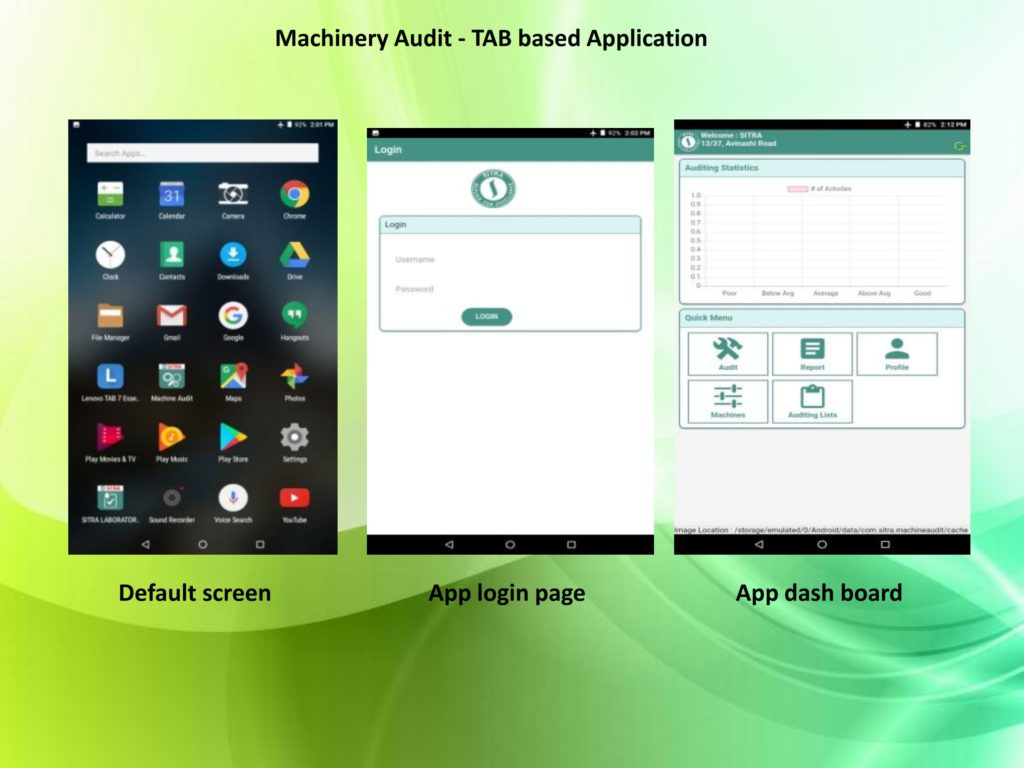

SITRA has developed a unique audit system for the assessment of conditions of machinery in the spinning mills using a tab based software.

A closer look on the factors that affect the quality and productivity of a spinning mill will reveal that they are usually dependent upon the mechanical condition of the machines. In other words, the functional parts of the machine must be in good working condition for any product to achieve the desired quality level. Proper maintenance practices, with appropriate frequencies to ensure the proper working of machines to the expected level, forms the basic structure of any maintenance program.

Major benefits of using this Tab

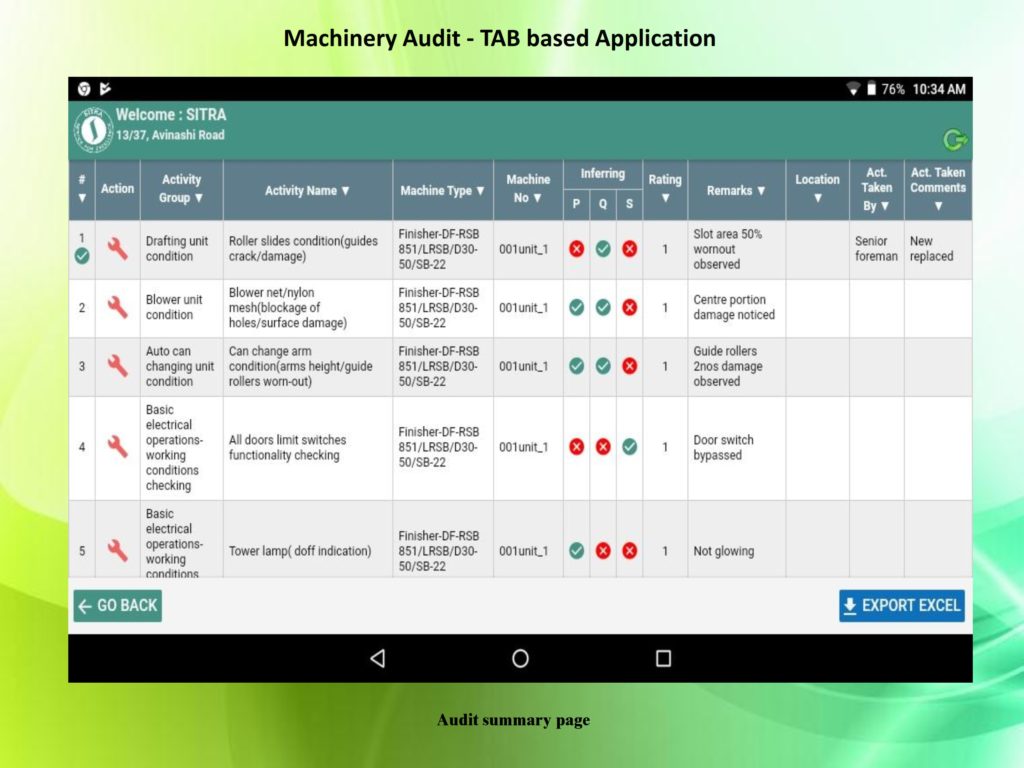

- Components which would require immediate attention (repair/renovation/ replacement) could be listed out for each machine. This would be helpful for the management to take a decision on modernizing the machines, budgeting and also market complaints.

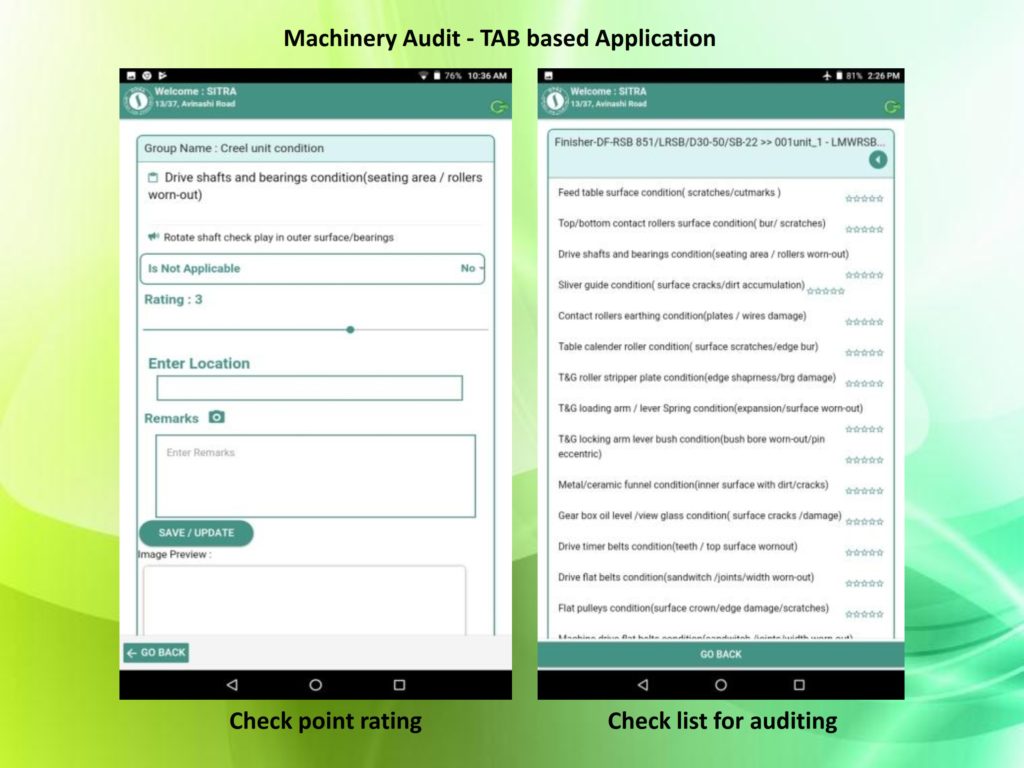

- The mills can re-visit frequencies of maintenance schedules based on the audit. By introducing new maintenance schedules/ activities it is possible to ensure better upkeep of the machines.

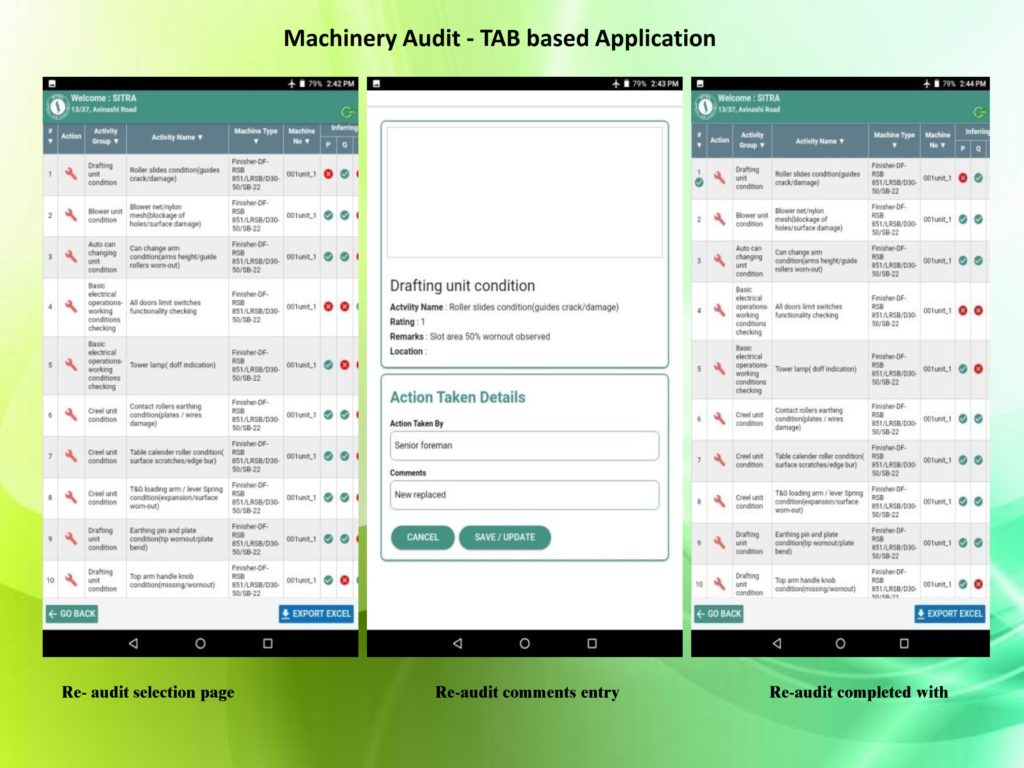

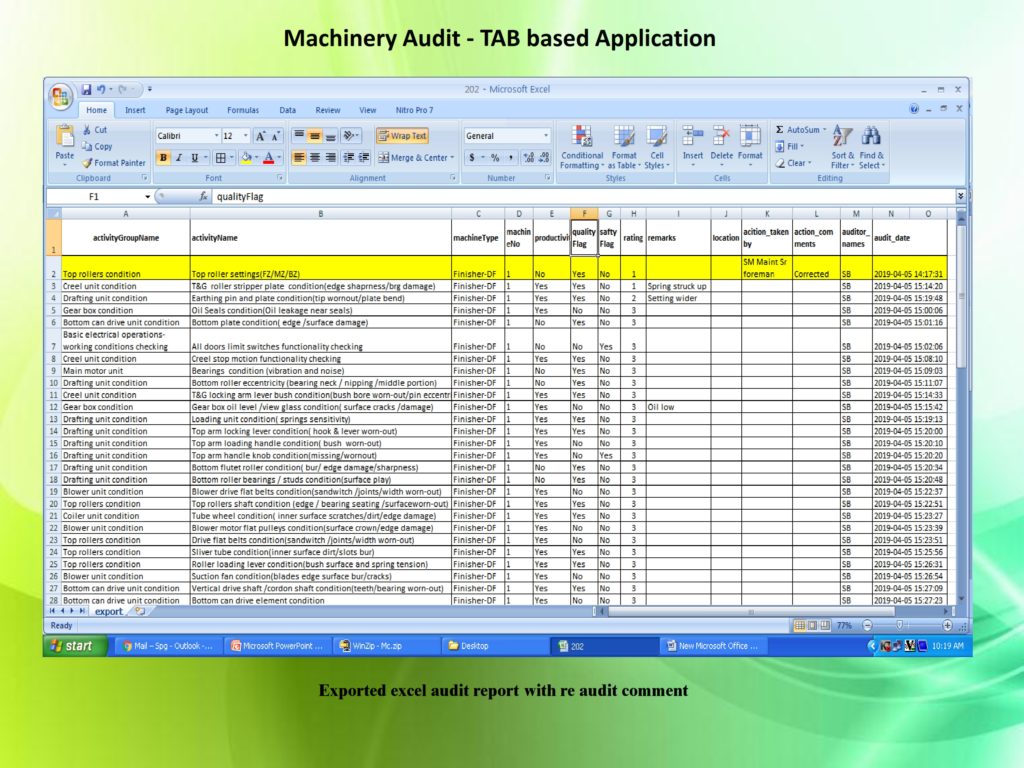

- The mills can take corrective actions based on the audit report of the points having deviations and the comments on the status must be recorded, which helps to evaluate the life cycle cost of the machine.

- This audit would also be helpful for mills to identify the machines that are responsible for the quality related market complaints.

- Overall rating of machines individually or as a group/ department-wise can be arrived at to evaluate the deviations between machine groups/models.

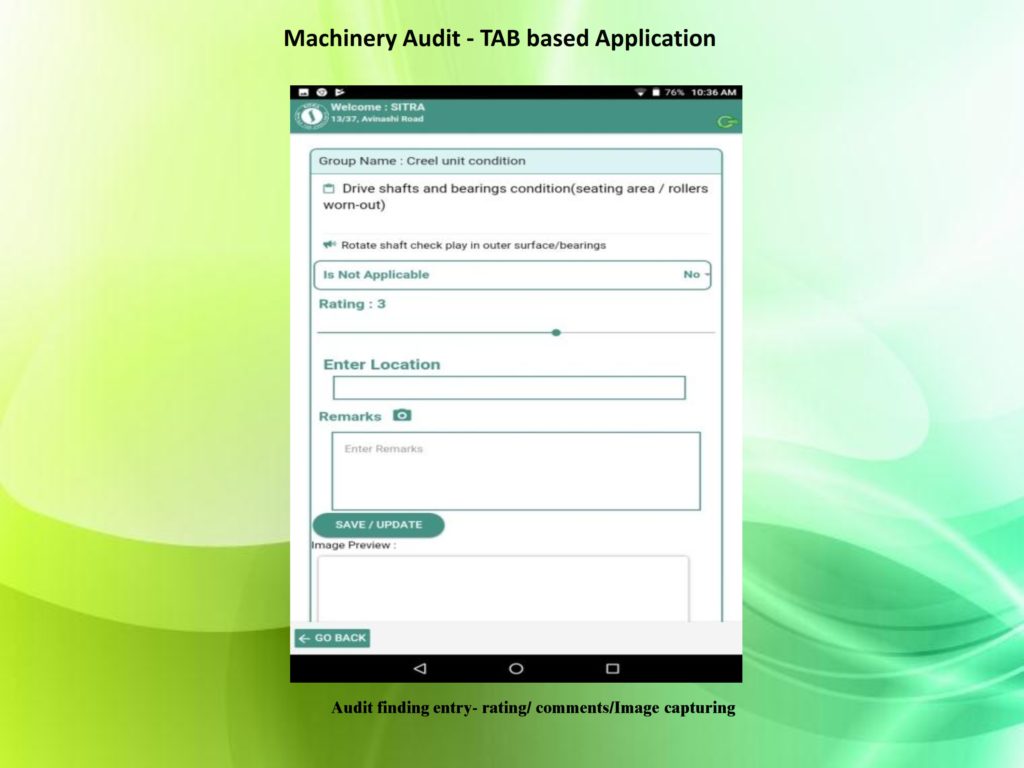

Glimpses of TAB based machinery audit interactive screens

Contact SITRA:

Spinning – Division

Mail : nkn@sitra.org.in /spg@sitra.org.in

Phone : 0422- 4251345 & 347