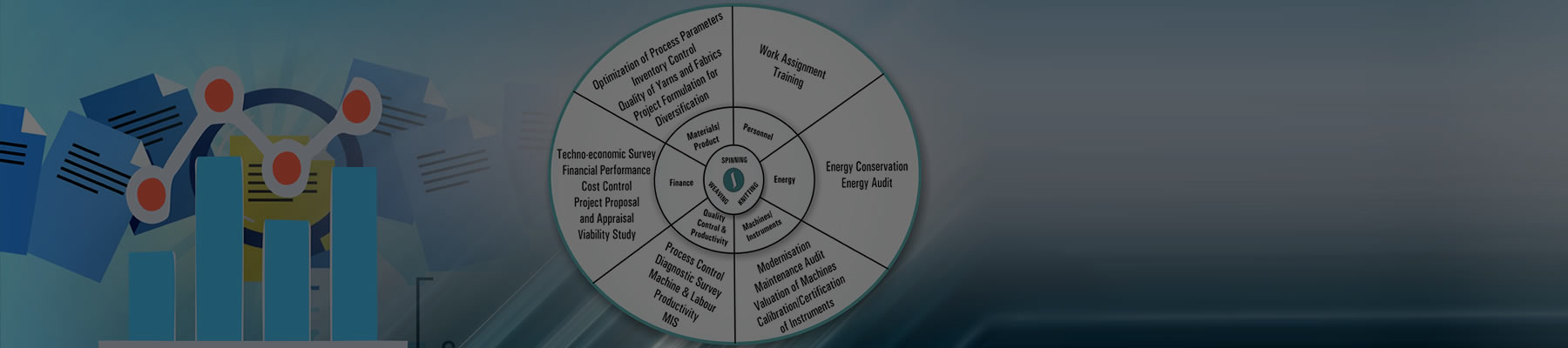

The Division offers a wide range of consultancy services to spinning mills such as productivity improvement, scientific work assignments for operatives, modernization of mills, techno-economic viability studies, cost reduction studies and machinery valuation. Besides the above, this Division regularly conducts two inter-mill studies:

i) Costs, Operational Performance and Yarn Quality (CPQ) study (once a year)

ii) Online survey of raw material cost and yarn selling price (monthly)

Inter-Mill Surveys

This unique study on inter-mill comparison of key parameters which affect cost of production, productivity and profit of spinning mills, was initiated by SITRA in the year 1997. Nearly 130 to 150 mills have been taking part in each CPQ study. The study which is being conducted once a year i.e., second quarter, covers more than 50 key parameters which include yarn sale value, raw material cost, net output value, power cost, salaries and wages cost, power consumption, labour and machine productivity, yarn realisation and quality, product diversification etc.

The report is found to be extremely useful to mills, based on which a number of measures have been initiated by them to reduce costs, realise higher yarn selling price and change the product-mix in order to maximise profits.

The survey is being conducted every month (since April 2013). About 100 mills spread all over the country have been participating in each study. The website designed for the online surveys is “rmcysp.sitraonline.org”. Besides commercial parameters, the survey also covers yarn quality, yarn realisation and production rate in ring frames.

It is an integral part of SITRA’s services right from its establishment in 1956. The two main purpose of this survey are: (1) to enable mills to judge their labour and machine productivity levels against the standard and also in relation to the performance of other mills and (2) to identify the areas, departments and operative categories where the productivity requires to be improved.

SITRA conducts inter-firm comparison studies on financial performance at regular intervals. The financial ratios form only a minor aspect in these studies, the main emphasis being on a comprehensive analysis of the financial and non-financial factors which contribute to inter-mill differences in profits. The contributions of various factors to the inter-mill variation in profitability are quantified.

Apart from the above regular surveys, the department also conducts several other surveys based on the requirement of the industry.

Consultation Studies

This study is a comprehensive assessment of a spinning mill’s working which covers the following aspects:

- Analysis of various components of cost (based on profit and loss statements).

- Labour and machine productivity.

- Condition of machinery and modernisation requirements.

- Yarn realisation and different wastes.

- Stores consumption.

- Packing materials cost.

- Work methods, materials handling and housekeeping.

- Training needs of workers.

The above study would identify the areas for improvement along with suggestions based on which mills could initiate suitable measures.

Spinning mills catering largely to domestic markets are expected to invest 3% to 5 % of sales turnover every year for modernizing their plant and machinery. On the other hand, the investment on modernization for exporting mills must be at a high level, say 6% to 7% of sales turnover per year so as to keep their productivity, quality and level of technology on a par with other competing mills. However, while planning for modernization, mills must consider the following aspects: Level and pace of modernization, allocation of priorities and return on investment.

The consultancy service on ‘Modernisation’, which would help mills to decide the right type of modernisation, covers the following aspects:

- Suitable modernisation scheme taking into consideration the condition of existing machinery, proposed product mix, availability of funds for modernisation and return on investment.

- Cost of modernisation.

- Benefits derived due to modernisation.

- Cost of production and profitability.

SITRA has been undertaking techno-economic viability studies for more than three decades. Mills as well as various financial institutions have been utilizing this service. The study would cover the following aspects.

- Analysis of various elements of cost (based on profit and loss statements) to identify the areas for improvement.

- Assessment of labour and machine productivity, yarn realization and wastes, condition of machinery and modernization requirement.

- Short term and long term measures for improving the performance and reducing the input costs.

- Cost of production and profitability expected for the improved working.

With the spinning mills operating with narrow profit margins, wrong estimation of count-wise conversion cost would result in producing more quantity of loss making products. Hence, correct estimation of conversion cost is highly essential while optimizing the count pattern/product-mix.

A discussion with a cross-section of the mills’ personnel reveals that some mills are not using the correct method of yarn costing. Moreover, they are not aware of the implication of a wrong method of estimation of conversion cost while deciding the product-mix. Many times, it can lead to either over costing or under costing of some counts, thereby affecting the profit realization.

Study on various elements of costing and cost control measures in spinning mill. Study the existing costing method of costing and suggesting the appropriate method of costing suitable for the mill based on their count pattern.

Over the past 4 decades, SITRA has been helping mills to fix work assignments for operatives in various departments based on scientific assessment. Work assignment studies jointly referred by both management and workers are also being taken up.

To enable mills to attend both labour and machine productivity together, SITRA has been offering a unique service package which would deal with the following aspects:

- Prevailing labour and machine productivity in comparison with other high productivity mills.

- Scope for increasing the work assignments of operatives, right from mixing and blow room to packing including automatic cone winders and TFO twisters.

- Measures to improve machine productivity i.e., production per spindle and spindle utilization.

- Achievable labour productivity levels for the proposed assignments.

- Existing work methods of operatives, housekeeping and materials handling.

- Training needs of operatives.

Maintaining the cost of production at optimum levels is one of the essential requirements for mills to stay successfully in the competitive market. SITRA has reoriented its services towards helping mills to reduce the input cost without any major investment.

This study will cover the following areas:

- Raw material cost: measures to control the different wasters at optimum levels.

- Wages cost: Scope for improving the existing labour and machine productivity levels.

- Other costs: Stores, packing materials and administrative overheads costs.

- Short-term and long-term measures to reduce the ,cost of production will be offered

SITRA has been undertaking machinery valuation studies on behalf of mills as well as various financial institutions for more than 3 decades. Value of the machinery will be estimated by taking into account a number of factors including the present condition, probable life in a 3- shift working basis, existing level of modernization and prevailing prices for new machinery of similar types.