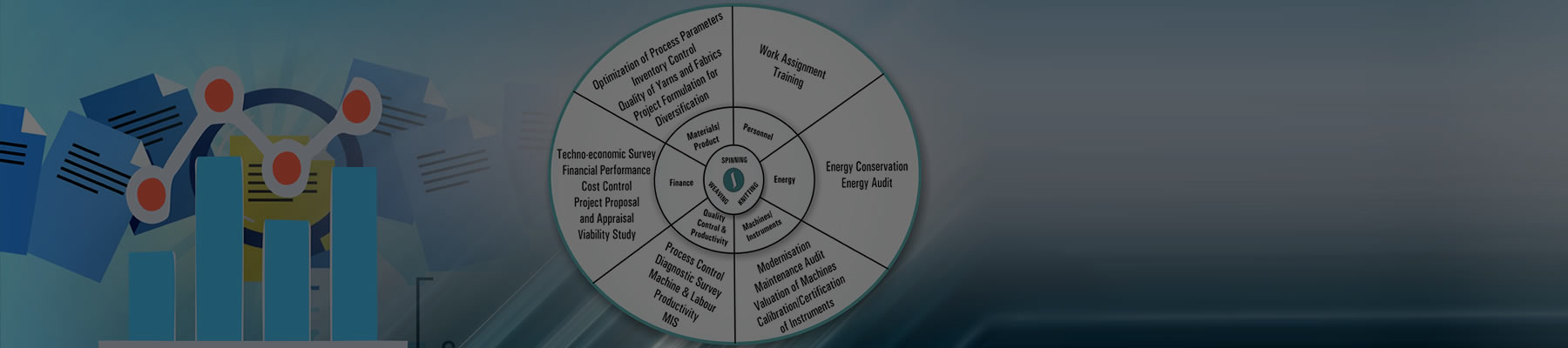

We at SITRA with knowledge base acquired through our prolonged research and interaction with the industry over 60 years along with our enhanced multi-varied experience with spinning industry as well as with machinery / fibre manufacturing industry assure to offer the following services with global excellence:

Quality Audit

Quality Control Schedules

- Man power requirement for quality control activities

- Control on in-process material quality

- Sampling techniques

- Arriving at the achievable yarn quality

- Process control measures

Machinery Audit

- Analysis of machinery condition

- Maintenance schedules and its frequency

- Man power requirement for maintenance activities

- Maintenance records

- Use of proper tools and lubricants

- Maintenance work methods and house keeping

- Overall rating is arrived

- Components which would require immediate attention could be listed out

- Decision on modernizing the machine and budgeting

- Identification of machines/ components responsible for poor yarn quality

- Re-visit the frequencies of maintenance schedules

- Streamlining the material flow

- Solution for quality related market

Other Consultancy Services

- Problems solving

- Process parameter optimization

- Troubleshooting for adhoc problems

- Yarn defect analysis

- Friction Spinning —Concepts and applications

- Technical support in processing non-conventional fibres and fancy yarn manufacturing

- Periodic Technical Visit (PTV) services for quality, maintenance and production areas

Research and Development

- Studies conducted in the field of effects of modern developments on fibre processing such as

- Change in fibre parameters during processing especially in cards and in drafting

- Effect of spindle speed on twist contraction levels

- Studies on various topics in spinning for better understanding and suitable modifications in the existing system continuously.

- Conducting trials for machinery/mechanisms development in collaboration with machinery manufacturers

- Sponsored projects from MoT, KVIC, NJB, etc.

Pilot Mill

Product Development

- Technical textiles from conventional fibres

- Technical textiles from high performance fibres

- Core yarn manufacturing in ring and friction spinning system

- Compact/Elitwist yarn spinning

- Fibre hooks measurement/ studies

- Processing of unconventional fibres such as pineapple, banana, Jute, coir, Sisal, hemp, Kenaf, etc.

- Processing of cotton, man-made fibres and their blends

- Processing of recycled cotton with organic/ polyester in ringframes as well as open-end spinning

- Arriving at the optimum process parameters

- Achievable yarn quality for different raw materials

- Rewinding study

- Processing of banana, hemp, pineapple and mil weed fibres in blend with cotton as well as with synthetics

- Measuring the degree of opening in blow room line using SITRA Openness tester

- Testing of sliver quality in Length Control Tester (LCT) towards optimizing the carding/drawing performance of synthetic & synthetic blends

- Package hardness testing

- Snarling Index testing

- Roving strength testing

- Compact blow room line for processing cotton and synthetics

- State of art cards with suitable specifications for separate processing of cotton and synthetics

- Latest high production comber

- Autoleveller draw frame

- Servo controlled latest generation speed frame with 16” lift

- Modern ring frame with - Suessen compact CDS system - Core yarn attachment with compacting system - Elitwist system

- Schlafhorst Autocoro 360 - Open end spinning

- Inverter controlled TFO with different pot size for coarse and fine yarn twisting at step less speeds for optimisation

- Precisim assembly winder